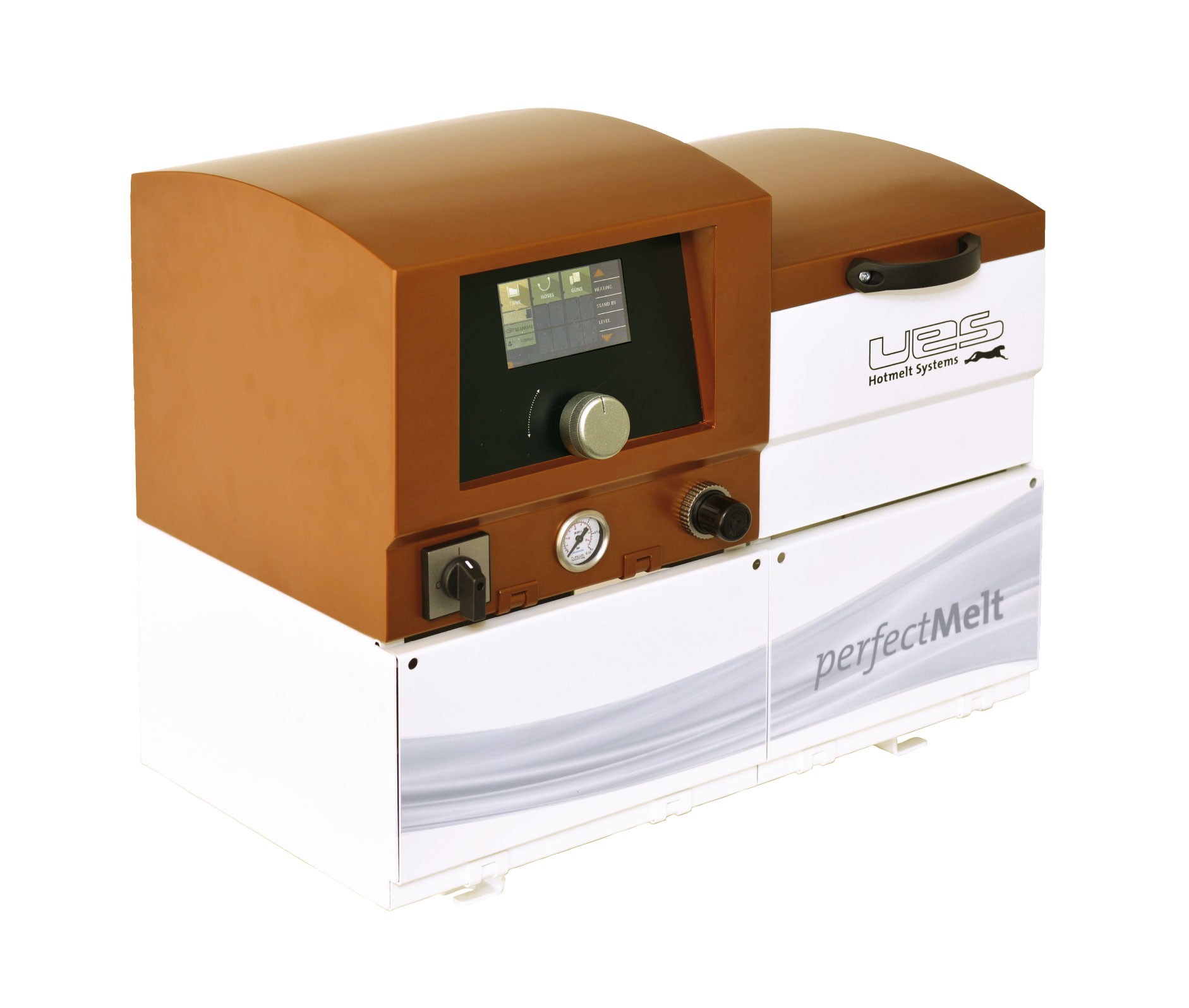

perfectMelt

- Energy saving intelligence

- One-hand operation possible

- Intuitive color touch display

- Melting exactly as required

- 2, 4, 6 or 8 hose connections

- Easy maintenance access

- Programmable timer control

- Maximum compatibility with temperature controllers for NI120, PT100, FECU, NTC sensors

The optimum character of the new perfectMelt is the best consequence of 20 years of experience in hotmelt technology. The fresh and appealing design was deliberately paired with a robust and stable steel housing.

The modern technology of the line integrates a lot of innovations for perfect operation in every hotmelt production unit. The dust- and dirt-resistant 4.3" colour display with touch-sensitive surface allows intuitive control of the system.

Since we are aware that not everything runs cleanly during production, the devices of the perfectMelt series can be operated with one hand via the safety input wheel and with gloves. Due to the ingenious positioning of the access flaps, your machine does not need to be dismantled in case of maintenance / cleaning, as all parts are accessible via the generous openings on the front.

The system series XL for all who need more perfection. Our XL series is designed for reliable melting and distribution of large quantities of glue. Do you need even larger quantities of glue? Then our Maxmelt is probably the right device for you.

As the successor to the UES Compact2 with almost identical outer dimensions, it is universally compatible with UES and comparable systems.

perfectMelt SE

- from 4 to 8 litres tank volume

- Intuitive color touch display

- 4 Hose connections

- Compatible with hoses / application heads from common suppliers

- one-hand operation

- Programmable timer control

- Maximum compatibility with temperature controllers for NI120, PT100, FECU, NTC sensors

The innovative basic table-top units with intuitive operation guarantee maximum energy and material savings. Due to their compact dimensions, they can be easily provided or mounted in mother machines.

Full control over the device is provided by digital I/O interfaces and signal contacts for the machine status for connection to the higher-level control of the parent machine.

The perfectMelt SE (Simplified Electronics) has the same intuitive touch display as our perfectMelt, as well as a week time switching program and is therefore also ideally suited for integration into fully automatic systems as an "OEM basic unit".

As the successor to the UES Compact and Compact SE with almost identical external dimensions, it is universally compatible with UES and comparable systems.

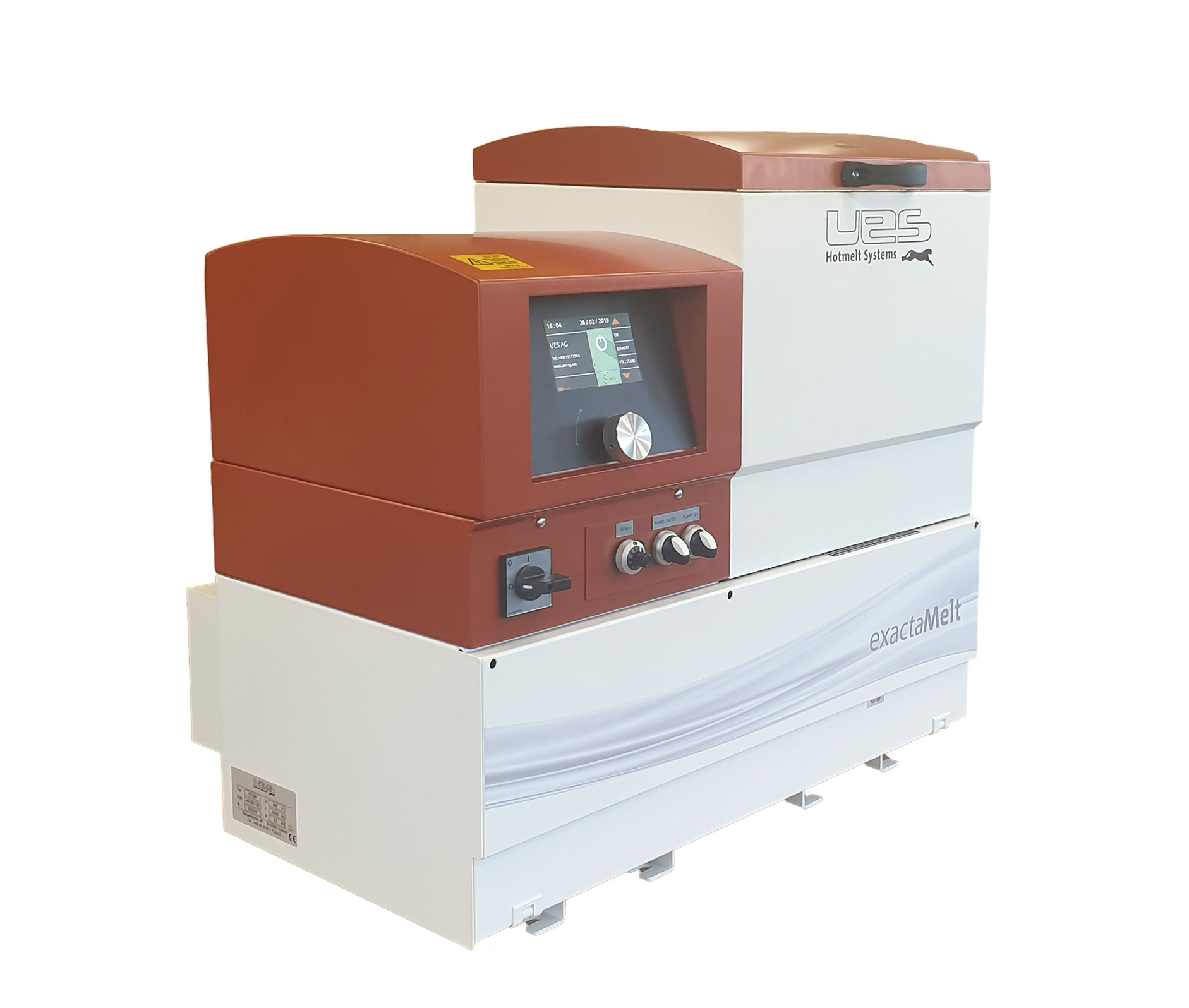

exactaMelt

-

exactaMelt

Optional 4 l or 8 l tank volume

Equipment

- Precision gear pump device

- Pump sizes from 0,87 - 7,3ccm

- one-hand operation

- Intuitive colour touch display

- 2 hose connections

- Operation without compressed air

- Maximum compatibility with temperature controllers for NI120, PT100, FECU, NTC sensors

-

exactaMelt

optionally 4 l / 8 l / 14 l / 20 l / 30 l tank volume

The exactaMelt series offers all advantages of the easy variant extended by the following features:

- manual or automatic motor control

- variable motor speed and delivery rate

- 2 / 4 / 6 / 8 Hose connections of your choice

Our exactaMelt devices with precision gear pumps of the highest quality provide for a Exactly even glue application without pulsation and pressure fluctuations, at any machine speed.

The materials used and the absence of compressed air reduce operating and maintenance costs.

The modern technology of the system integrates a lot of innovations for perfect operation in every hotmelt production unit. The dust- and dirt-resistant 4.3" colour display with touch-sensitive surface allows intuitive control of the system. All variants are equipped with the tried and tested safety input wheel, enabling one-handed operation - even with gloves.

MaxMelt

from 25 to 100 litres tank volume

Equipment

- Proven perfectMelt control

- Digital inputs and outputs

- High melting capacity

- Separate heating circuits for tank and glue distributor

- PT 100 sensors

- Teflon-coated cast aluminium tank

- Extra large tank opening with overflow protection

- Pump drive with three-phase motor and frequency converter

- pressure relief valve

- glue drain screw

The MaxMelt series impresses with its high melting capacity and high flow rates. The large stand-alone units are indispensable when it comes to continuous application of high quantities of glue.

Maxmelt systems are usually equipped according to customer specifications. Special requirements such as an extended control system, unusual connection options or optimisation for materials other than hotmelt are nothing unusual. Of course, we also offer systems with basic equipment.

The large tank options of the MaxMelt series reduce the refilling effort, which can be further reduced by combining it with a PowerFill. The Maxmelt series is equipped with separate heating circuits for the tank and glue distributor so that the glue maintains the same temperature everywhere in the machine, even with large quantities. Modern sensor technology ensures that the temperatures do not deviate by more than 1 °C anywhere.

PowerFill

- Suction conveyor with feed hopper and pick-up

- 3 meter flexible transport hose

- Double-wallen tube for optimizing the dew point

- Large air filter for optimum air exchange

- Optimized adhesive supply prevents hot vapors from entering the hose

- Sensor and control for glue filling quantity and automatic on/off switching

- Adapter plate replaces tank cap

Downtimes because glue was forgotten to refill? Contamination of the glue and the tank system due to frequent opening of the tank? Contamination of the machines due to overfilling?

The automatic granulate conveyor PowerFill solves these problems! PowerFill is simply mounted on the tank filling opening of the hotmelt system instead of the tank cover and the lance is placed in the storage container at the end of the conveying hose. A sensor detects the filling level of the glue in the tank unit and automatically switches the granulate conveying on or off when the set quantity is reached. The lance destroys possible clumping of the material by a vibrating movement.

The system can be retrofitted to any common glue applicator, regardless of the manufacturer.

| Kontakt Breuershofstr. 48 47807 Krefeld |

|

| Telefon: +49 (0) 21 51 72 95 0 |

|

| E-Mail: info@ues-ag.net | |

| Youtube |